Last April, a rocket departed from the Mid-Atlantic Regional Spaceport in Virginia bound for the International Space Station. Six hundred miles away in Montreal, Roozbeh Safavieh, PhD’14, was watching a livestream of the launch from his office. As the founder and CEO of Sensoreal, Safavieh had a lot at stake in the mission. Included among the rocket’s nearly four tons of cargo was a Sensoreal “lab-on-a-chip,” a small device that promises to revolutionize astronaut healthcare.

“It was a unique moment as we could see the result of our four years of work,” says Safavieh. “We were quite excited.”

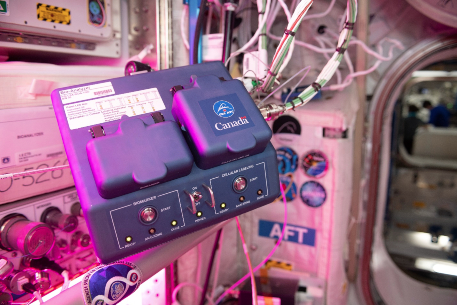

Sensoreal’s lab-on-a-chip will spend the next five years on the International Space Station (ISS), undergoing tests. It is one of two instruments included in the Bio-Analyzer, a tool developed by the Canadian Space Agency to monitor the health of astronauts while they’re in space. The Bio-Analyzer (left, seen aboard the ISS) is meant to allow point-of-care diagnostics in orbit using small samples of bodily fluids like blood and saliva.

The lab-on-a-chip developed by Safavieh and his colleagues at Sensoreal leverages “microfluidics,” the catch-all term for devices that control tiny amounts of fluids. It’s about the size of a smartphone and is criss-crossed with tiny channels that aren’t much larger than strands of human hair. Fluids are automatically routed where they need to go. It’s a bit like programming a computer chip, except instead of shuttling electrons across a circuit board, the lab-on-a-chip is moving blood cells.

Each lab-on-a-chip made by Sensoreal can be completely customized for different uses. The one that was sent to the space station is designed to analyze proteins in astronauts’ blood to study the signaling pathways of the body’s cells. All the astronauts have to do is prick their finger to supply less than a milliliter of blood to the device and the Bio-Analyzer’s computers do the rest.

Astronauts undergo rigorous health evaluations before they leave Earth, but the Bio-Analyzer stands to open up a new frontier of space medicine. Prior to its arrival, drawing blood in microgravity wasn’t much different than it was on Earth. Astronauts would use a large needle and collect samples in test tubes, which they would store in the space station’s freezers until they could be returned to Earth. This degraded the sample quality, but it was the only option available. The Bio-Analyzer made rapid in-orbit blood tests possible for the first time.

This is important for understanding how the space environment affects human health, Safavieh says. Astronauts experience all sorts of biological changes induced by the lack of gravity, exposure to solar radiation, and other factors. Many of these changes manifest in the blood, such as the levels of different proteins or the number of blood cells, which are the two factors the Bio-Analyzer is designed to measure. Rather than simply having a before and after understanding of astronaut health, the Bio-Analyzer allows these changes to be tracked while the astronaut is still in orbit.

Only a month after arrival, Canadian Space Agency astronaut David Saint-Jacques, MedResident’07, gave the Bio-Analyzer’s lab-on-a-chip its first trial. He used a small sample of his own blood to test for five different protein biomarkers that gave a general indication of his overall health. For Safavieh, the test marked the culmination of several years of designing, building, and getting approval to fly the hardware — but in many ways it’s just the beginning.

Safavieh has been working on microfluidic technologies for nearly two decades, first as an undergraduate at Iran’s Sharif University of Technology and then as a master’s student at University College London. In 2008, he decided to pursue a PhD at McGill because of its strong biomedical engineering program and began working in Professor David Juncker’s micro and nanoengineering lab. As a student, Safavieh filed his first patent with Juncker for a method of creating microfluidic circuits using yarn after noticing how liquid moved across the string on a teabag.

“Roozbeh was always an out-of-the box thinker,” says Juncker. “The Earth may have been a little too small for him so he went to space.”

Safavieh founded Sensoreal in 2013 to make microfluidic lab-on-a-chip devices for the medical industry and teamed up with three other McGillians — Kate Turner, MEng’14, Alessandra Robillard, BEng’15, and Pooya Saberi, MEng’19 — to make it happen.

Safavieh says the company was originally focused on point-of-care applications on Earth, but it soon became clear that the ability to perform laboratory procedures using a small chip would also be useful in space. Astronaut healthcare is going to become an increasingly important issue as humanity prepares to establish a permanent human presence on the moon — and eventually Mars — but the medical technology needed for the next great leap was lacking. Safavieh realized that microfluidics could offer a valuable approach.

“The chip works without any pumps or valves, which makes the device portable, self-contained, and self-powered,” Safavieh says. “At first we didn’t envision it being used for space, but the product fits the space market.”

The value of Safavieh’s technology isn’t limited to extraterrestrial applications. Blood tests remain prohibitively expensive or inaccessible for much of this planet’s population. Sensoreal is currently developing the device for diagnosing infectious diseases at the point-of-care. Safavieh says the ability to understand whether an individual is infected with a given disease without needing to wait days for a laboratory to return results on a blood sample could drastically reduce the overprescription of antibiotics since they will only be prescribed to individuals that actually need them, rather than as a precautionary measure.

Safavieh’s microfluidic technology also has more esoteric uses. In October, Sensoreal signed a contract with the Canadian Food Inspection Agency to develop a lab-on-a-chip that is able to detect the presence of marine biotoxins in shellfish. This, he says, allows fisheries to test that a given batch of shellfish is safe for human consumption on site without needing to send samples of the shellfish for testing.

Safavieh’s technology may be small, but it could play a role in making some big changes around the world — and beyond.